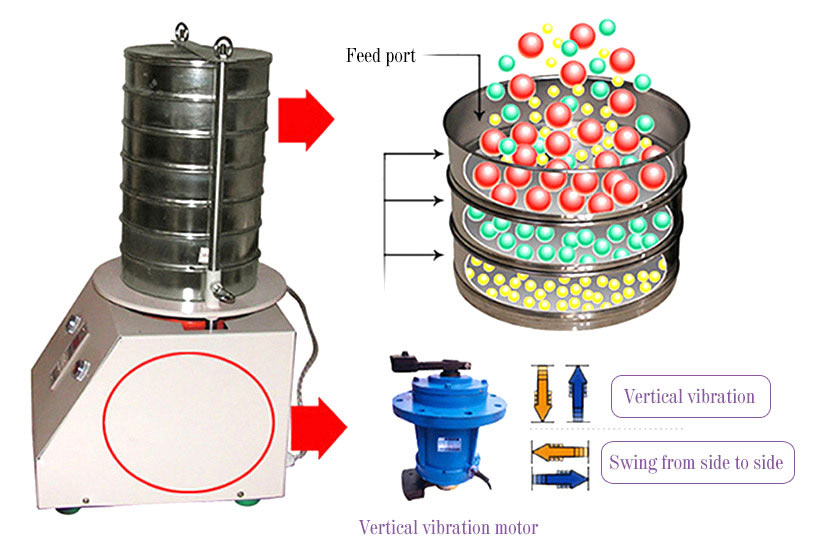

Lab Vibrating Screen is a particle size analyzer with timing and automatic shutdown, which can ensure test repeatability, comprehensive functions and simple operation. It can precisely separate a granular material into 2-7 particle segments at the same time. Accurate screening, filtration and detection of material particle size structure, liquid solid content and sundry amount are mostly carried out on the laboratory bench.

Standard Lab Vibrating Screen

The number of screen frames that can be placed: 1-8 layers

Measuring range: 0.025mm~3mm

Timing range: 0-99min

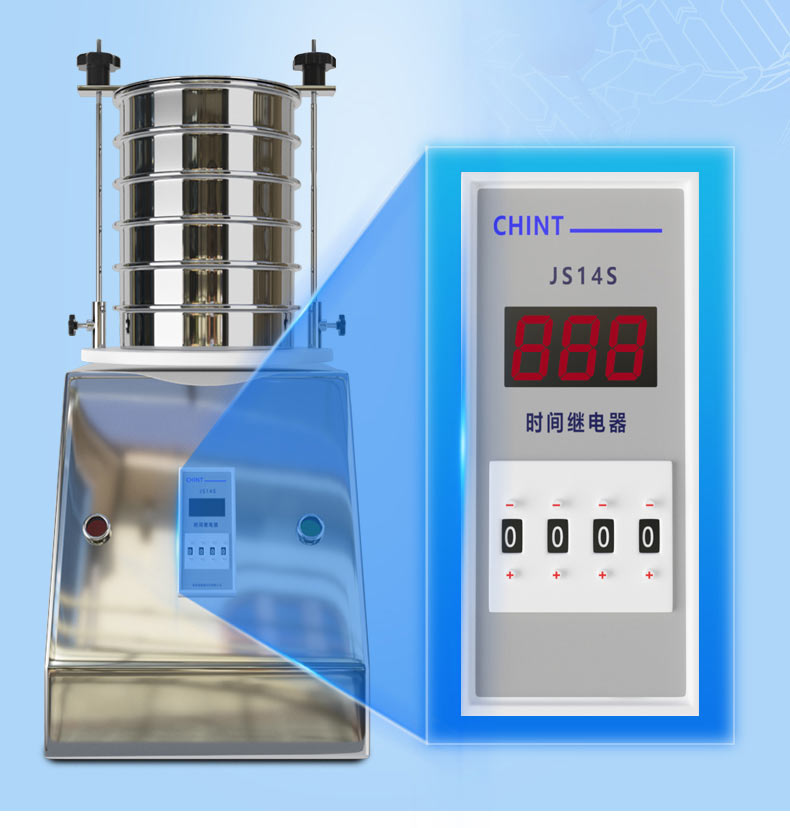

Standard Lab Vibrating Screen: suitable for the detection of laboratory powder, granule and liquid materials, and can be equipped with an ultrasonic system

With the vertical motor as the power source, it is transmitted to the sample through the sieve tray for grading.

clapping Lab Vibrating Screen

The number of screen frames that can be placed: 1-8 layers

Measuring range: 0.025mm~3mm

Timing range: 0-99min

clapping Lab Vibrating Screen: suitable for inspection of ordinary abrasive grain size composition, superhard material production classification and material size composition inspection

In addition to the standard circular shaking, a clapping longitudinal motion is added to obtain more fine samples.

Ultrasound Lab Vibrating Screen

The number of screen frames that can be placed: 1-8 layers

Measuring range: ≥0.02mm

Ultrasound Lab Vibrating Screen:High mesh over 200 mesh or fine powder that is easy to agglomerate and charged with static electricity. Such as pharmaceutical powder, robe powder, electromagnetic powder, metal powder, etc.

Ultrasonic system is installed to realize sample analysis with high-frequency and low-amplitude movement

According to the material

75/100/200/300/400mm

Common Standard Sieve Shaker material, resistant to wear and corrosion, no rust, and high hygiene standards.

200/300mm

Good ductility and is used for special sample screening. It is softer than stainless steel.

200mm

Non-magnetic material and metal material, used for sieving of special fibers, chemical additives and samples with active properties.

1. SUS304 stainless steel material, smooth and hygienic, does not contaminate the sample

2. There is no burr in the section, which meets the safety operation standard

3. A single machine weighs only 45kg, small in size, convenient for handling and operation, and does not occupy space

4. During the screening process, the machine produces vertical and left-right shaking movements, and the screening effect is good and the precision is high.

5. The 0-99 minute timer relay ensures the accuracy and repeatability of sample analysis.

Lab Vibrating Screen is mainly used for inspection of particle size composition of ordinary abrasives and production classification and particle size inspection of superhard materials, such as scientific research and production, laboratories, quality inspection rooms of departments such as geology, chemical industry, cement, medicine, and chemical industry. Precise screening, filtering, testing, etc. of the particle size structure of the material, the content of liquid solids and the amount of sundries.

| Serial number | name | unit | data | |

| 1 | Standard screen body | Floor | 8 | |

| 2 | Screen diameter | mm | φ200φ2100φ275 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | noise | dB | ≤50 | |

| 3 | Feeding amount (one-time) | g | ≤200 | |

| 6 | amplitude | mm | ≤5 | |

| 7 | Motor | Voltage | V | 220 |

| Rotating speed | r/min | 1420 | ||

| power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Overall quality | Kg | 25 | |

bismuth tungstate--500 mesh

sieve shaker for testing soil

how to use sieve shaker